Fiocchi Ammo

Fiocchi: By Shooters For Shooters

When Giulio Fiocchi—a bank manager in Milan, Italy—inspected a musket and blackpowder manufacturer in nearby Lecco that defaulted on a loan in 1876, he found all the right ingredients to launch Fiocchi Ammunition. The borrower was insolvent, and with little chance of paying back the funds its skilled metalworkers were about to be jobless.

Although armed with little gun knowledge at the time, he understood the recent introduction of metallic cartridges signaled a revolution in the firearm industry. His brother Giacomo, who had studied engineering at the University of Milan, visited the closing facility and agreed it was ideal for a company specializing in the new ammunition. Giulio’s bank floated a loan, musket production ceased and by 1877 cartridges were coming out of the factory under the Giulio Fiocchi Enterprise name.

Fiocchi During the World Wars

Giulio had 13 children and his belief in family showed with workplace benefits—a rarity at the time. By 1904 he was building employee housing and paying wages generous enough for workers to purchase the homes.

Women were hired long before it was accepted practice and a nursery was established for staff-members’ children. The efforts built a loyalty so deep that it’s not uncommon for an employee today to be a third- or fourth-generation member of their family working at Fiocchi.

The company thrived and during World War 1 Italy relied on Fiocchi to supply its military with ammunition. Carlo inherited the company in 1916 after his father, Giulio, died.

Then Word War II struck. Nazis occupied the factory, only to attempt its destruction once it became obvious Axis powers would be driven from Italy. The effort was thwarted by loyal employees, but the plant ultimately fell victim to Allied bombing.

Family members faced a difficult decision after the war—rebuild or abandon the business? They decided to pour savings into the company, virtually starting from scratch. Everything was retooled, re-machined and modernized, putting it decades ahead of many of its competitors that probably considered emerging from the global conflict unscarred an asset. Without help from the Marshall Plan, the factory rose from the ruins with the latest in technology.

U.S. Arrival

Fiocchi entered into a partnership with Smith & Wesson in the 1950s and opened a plant in Alton, IL—the company’s first entry into the United States. The firms parted ways, though, and the fabled Italian ammunition maker temporarily lost its American footing.

In 1983, sensing the growth of the shooting sports stateside, the company returned by establishing Fiocchi of America in Springfield, MO. They selected Missouri for its shipping-strategic central location, and the company’s ammunition was once again available in the U.S.

Keeping up with the tastes of enthusiasts stateside, however, proved a logistical challenge when loaded shotshells were shipped long-distance from Italy. A year and a half later, the company secured property for a new plant near Ozark, MO, where 90 percent of its American employees work today and more than 75 percent of all Fiocchi ammunition sold in the United States is assembled.

Wads and empty primed hulls are imported from Bashieri & Pellagriand Gualandi and Fiocchi Munizioni, respectively, but all propellant comes from U.S. sources. As for the projectiles, the company has solid working relationships with some of America’s finest.

Today it loads bullets from Hornady and Sierra Bullets, ensuring the kind of exterior and terminal ballistics shooters expect. Naturally, the company has a full lineup of full metal jacket cartridges for high-volume shooters, as well as other styles—even some blanks—from which to choose. Fiocchi has NATO certification, which means much of its ammo is suitable for use by all militaries in the alliance.

The fact that the company’s U.S. sales have increased 500 percent since 2005 speaks volumes for the quality and reliability of its products. A lot that is attributable to Fiocchi’s dedication to innovation in shotshells—where customized loads for its stable of title-holding international shotgunners often migrate into commercial offerings.

Fiocchi Exacta Target Shotshells

Look no further than Fiocchi USA’s Exacta Target Loads if you’re serious about busting clays. The company has developed the kind of shotshells that win at the International level for more than five decades, and the experience shows. They’re available in different load weights and velocities, each tailored to fit different shooter preferences and the nuances of the shotgun they shoulder.

The Little Rinos, for example, are 12-gauge 2 3/4-inch shotshells with a single ounce of either No. 7 1/2 or No. 8 lead shot, your choice. Regardless of the pellet size, muzzle velocity is identical at 1,250 fps. Turning the load up a notch, White Rinos—also part of the Exacta Target line—come in the same length shotshell, and feature 1 1/8-ounce loads of lead shot (same two shot sizes) that still leave the barrel at 1,250 fps. The interior contents are similar in the Crushers and Super Crushers, but muzzle velocities increase to 1,300 fps. Exacta Target loads are also available in 20-gauge and .410-bore. When a title is at stake, Fiocchi understands small tweaks can make a world of difference.

Fiocchi Shooting Dynamics Target Shotshells

This line is the official ammo of the Professional Sporting Clays Association and there’s good reason. One or 1 1/8 ounce of chilled shot rides atop a one-piece shotcup in the 12-gauge flavors, and when coupled with the company’s precision hull production, delivers the flight reliability required for high-scoring consistency. It’s also available in 20-gauge versions.

Fiocchi Hunting Ammo

The company hasn’t forgotten about hunters and offers a variety of options that include its leaded Game and Target line, Speed Steel tailored for waterfowlers, Golden Pheasant and others. Blanks and rubber buckshot ammo ideal for hazing nuisance wildlife in rural settings are also available, as well as slugs and buckshot tailored for law enforcement, home defense and hunting.

Fiocchi Centerfire Ammo

The unrivaled performance of Fiocchi America shotshells unjustly overshadows its centerfire cartridges. It offers a complete-line of full-metal-jacketed loads for high-volume shooters on a budget, but if connecting at distance is your game, take a close look at the Exacta Match offerings. They feature Sierra MatchKing Bullets and those correspondingly high ballistic coefficients. For hunting the company produces cartridges with Hornady’s famed V-Max or InterLock bullets. Self-defense enthusiasts will appreciate the hollow point loads and the renowned Hornady XTP (eXtreme Terminal Performance) version. There’s something for everyone, whether you’re a hunter, carry concealed or enjoy ringing steel at 1,000 meters.

Fiocchi is still a family-owned and operated business to this day.

-

Fiocchi 22 LR 40 Grain LRN - 50 Rounds

$6.45Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 40 Grain Bullet Type Lead Round Nose (LRN) Use Type plinking at the range, Subsonic Casing Type Brass Quantity 50 Ammo Caliber 22 Long Rifle (LR) Manufacturer SKU 22FLRN Primer Type Rimfire Magnetic No UPC Barcode 762344710006 Cost Per Round 12.9¢ per round When you want something easy to shoot and inexpensive, the 22 LR is the perfect round for you. This exceptionally popular round is used all over America and is fantastic for all types of shooting, including match shooting, varmint and small game hunting, teaching your children how to shoot, and plinking around. With the incredibly low recoil, quiet report, fantastic accuracy, and low prices that come with this round, you won't be looking for another cartridge.

Fiocchi was founded back in 1876 and is still owned and managed by the same family that started this prestigious company in Italy nearly a century and a half ago. These 40 grain, lead round nose, brass cased, boxer primed rounds fire at 1070 feet per second and are perfect for all your range training needs. With these inexpensive yet highly reliable and accurate rounds, you have everything you need to teach your children how to shoot, plink around in your woods, or train rigorously at the range.

-

Fiocchi 9mm 115 Grain FMJ – 1000 Rounds

$244.85

$224.85

Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 115 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 1000 Ammo Caliber 9mm Luger (9x19) Manufacturer SKU 9AP Primer Type Boxer Magnetic No UPC Barcode 762344860008 Cost Per Round 22.5¢ per round Fiocchi ammunition is always a safe bet for your shooting needs. This range load is a great replacement for expensive hollow points when you're slaying paper targets. It fires a light 115 grain full metal jacket (FMJ) bullet at a muzzle velocity of 1,200 feet per second, slightly faster than other standard pressure loads; the FMJ projectiles use brass jackets rather than copper in order to maintain stability with the increased velocity and are proven to produce accuracy worthy of competitive use.

Most Fiocchi ammunition sold in the US is loaded in Ozark, Missouri with the balance being imported from Lecco, Italy. Fiocchi has been in business since the 19th century and has taken off in a big way in the US in the last several years due to the reasonable price and impressive quality of its ammo.

These cartridges use non-corrosive Boxer primers and reloadable brass cases. Each case contains 1,000 rounds--perfect for bulk savings.Customer Reviews

-

good price and quickly shipped.

-

Bought these to re-stock supply. I have always liked Fiocchi ammo.

Review by GR (Posted on 7/15/2024)

-

Top Accuracy

-

I got 1210 fps and the best accuracy from Fiocchi 115 gr in a 4 1/4” M&P. Best fmj ammo I have used.

Review by StraightUp (Posted on 1/15/2022)

-

As usual the experience was great. Making the order and arranging the shipping went quickly. I have been using the Fiocchi since it came on the market with great results.

-

Wideners is a great place to shop and the Fiocchi brand is a great performer.

Review by Lee (Posted on 4/8/2020)

-

Shoots straight everytime

-

I live 10 miles from where this ammo is made but that doesn't affect my review. I want ammo that doesn't jam or miss fire and is cheap to use at the range having fun. To sum it up, this ammo is all of that and more. Buy it, you won't regret it.

Review by Jim3000gt (Posted on 11/28/2019)

-

Great range/practice ammo

-

I have shot thousands of rounds of this ammo and I don't recall any issues. Seems to burn clean and hits what I aim at.

Review by Eric (Posted on 9/26/2019)

-

just get them

-

they work with out difference in each fire. they are pleasing to look at they work nuff said

Review by shoot em (Posted on 6/3/2019)

-

Very clean, accurate, reliable ammo!!!

-

Fiocchi ammo has always been, & I hope & expect, will always be, great, clean, accurate, reliable ammo for me. Their brass is great for reloading as well!!! You can trust this ammo to get the job done, whether target practice, or an action pistol match!!!

Review by Mark (Posted on 6/13/2016)

-

-

Fiocchi Pistol Shooting Dynamics 9mm 124 Grain FMJ - 1000 Rounds

$259.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 124 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 1000 Ammo Caliber 9mm Luger (9x19) Manufacturer SKU 9APB Primer Type Boxer Magnetic No UPC Barcode 762344860763 Cost Per Round 26¢ per round This 9mm Luger ammunition from Fiocchi comes in a 1,000 round case that's sure to push your per-shot costs down. It is a standard pressure range load ideal for high volume target practice with both full-size and compact firearms.

Each round fires a medium weight 124 grain full metal jacket bullet at 1,150 feet per second, producing recoil and external ballistics similar to those of many popular carry loads.

Most Fiocchi ammo sold in the US is also made in the US, at a manufacturing facility in Ozark, Missouri. The remainder is imported from Lecco, Italy. Both locations use non-corrosive primers and reloadable brass cases in their products.

-

Fiocchi 9mm 115 Grain FMJ – 50 Rounds

$14.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 115 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 9mm Luger (9x19) Manufacturer SKU 9AP Primer Type Boxer Magnetic No UPC Barcode 762344001623 Cost Per Round 29.7¢ per round This 9mm Luger ammunition from Fiocchi delivers accurate, reliable performance at a reasonable cost. Each cartridge in this box of 50 fires a light 115 grain full metal jacket bullet at 1,200 feet per second, slightly faster than most target loads. This bumps recoil up a little bit and provides a more realistic training experience that simulates full power carry ammunition.

This is not +P ammo, so it can be used in subcompact or older firearms not rated for high pressure cartridges. It uses non-corrosive Boxer primers and reloadable brass cases.

A majority of Fiocchi ammunition sold in the US is loaded in Ozark, Missouri, with the rest coming from the company's headquarters in Lecco, Italy.

-

Fiocchi Pistol Shooting Dynamics 9mm 124 Grain FMJ - 50 Rounds

$15.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 124 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 9mm Luger (9x19) Manufacturer SKU 9APB Primer Type Boxer Magnetic No UPC Barcode 762344001678 Cost Per Round 31.7¢ per round If you own a handgun that takes 9mm cartridges, you can get the high-quality ammo you need for training, practice, and plinking by ordering this 50-round box from Fiocchi. You’ll get 124-grain full metal jacket ammunition that is reliable and effective, allowing you to get the practice you need to maintain proficiency with your firearm.

These rounds are designed for high-volume target shooting in autoloading 9mm handguns. The full metal jacket will give you smooth performance from the magazine to the chamber, and will result in less fouling in the barrel, helping you maintain superior accuracy throughout a full day of target practice. The 124-grain bullet delivers fast, powerful performance, creating a top-notch shooting experience.

Fiocchi’s Shooting Dynamics line is specifically made for target shooting. It uses boxer primed cases with non-corrosive primers and clean powders. Fiocchi is an Italian manufacturer with a long, rich history of creating top-quality ammunition supplies.

Customer Reviews

-

Very Well Manufactured

-

I am really impressed with this ammo. It looks very well manufactured and polished. After hitting the range, they ran as well as they looked! Great consistent ammo that didn’t dirty up my gun.

Review by Mike (Posted on 4/18/2023)

-

-

Fiocchi 380 Auto 95 Grain FMJ – 1000 Rounds

$339.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 95 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range, Subsonic Casing Type Brass Quantity 1000 Ammo Caliber 380 Auto (ACP) Manufacturer SKU 380AP Primer Type Boxer Magnetic No UPC Barcode 762344029894 Cost Per Round 34¢ per round Compact pistols aren't always the most fun to shoot, but if you depend on a .380 ACP handgun for self-defense, you owe it to yourself to train with it as well. This 1,000 round case of ammunition from Fiocchi can help you get the trigger time you need at a reasonable price.

Each cartridge in this case fires a 95 grain full metal jacket bullet at a muzzle velocity of 960 feet per second. This is typical for the .380 Auto and delivers ballistics and felt recoil similar to those of most carry loads.

This ammo is packaged in boxes of 50, with 20 boxes in each case; it uses non-corrosive primers and reloadable cases.

-

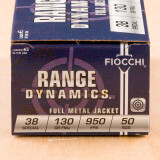

Fiocchi Pistol Shooting Dynamics 38 Special 130 Grain FMJ - 1000 Rounds

$419.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 130 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range, Subsonic Casing Type Brass Quantity 1000 Ammo Caliber 38 Special Manufacturer SKU 38A Primer Type Boxer Magnetic No UPC Barcode 762344860336 Cost Per Round 42¢ per round This .38 Special ammunition is an inexpensive, dependable training load for your revolver. Each cartridge in this bulk priced case of 1,000 fires a medium weight 130 grain full metal jacket bullet at a muzzle velocity of 950 feet per second. The FMJ bullet makes this ammo suitable for virtually all indoor ranges; however, note that use of FMJ is discouraged in some rifles with tubular magazines.

Compared to other .38 Special loads, this is a relatively powerful round that will serve well as a stand-in for hot defensive ammo by producing realistic levels of recoil and excellent accuracy. However, it is still within the standard pressure range and can be used in firearms not rated for +P cartridges.

Fiocchi ammunition is loaded in both the USA and Italy using reloadable brass and non-corrosive primers. -

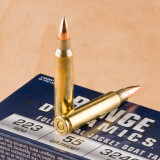

Fiocchi 223 Rem 55 Grain FMJ – 1000 Rounds

$424.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 55 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 1000 Ammo Caliber 223 Remington Manufacturer SKU 223A Primer Type Boxer Magnetic No UPC Barcode 762344861326 Cost Per Round 42.5¢ per round Get in your range time without breaking the bank, with this case of Fiocchi ammunition.

This case of 1000 rounds is loaded by the increasingly popular Fiocchi Ammunition Company. Fiocchi produces a wide variety of range training, self defense, and hunting ammunition, and is sold in the US and several other countries around the world. The Italian based ammo manufacturer primarily produces quality yet affordable brass cased ammunition and uses a variety of projectiles made both in-house and by other highly reputable companies.

This ammunition is loaded with a 55 grain full metal jacket bullet, and has muzzle velocities of about 3,200 feet per second. This ammo is great for all types for range training and tactical training, including high precision marksmanship training. This ammo is also cheap enough to make a good plinking round and accurate enough to be used with hunting small varmints, although it does not expand on impact with its target. Order your case today, and safe shooting!

Customer Reviews

-

Quality and price where the best we could find.

-

Very happy with the purchase. Arrived in a very timely manner.

Review by Kathy (Posted on 1/2/2024)

-

-

Fiocchi 25 ACP 50 Grain FMJ - 1000 Rounds

$448.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 50 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range, Subsonic Casing Type Brass Quantity 1000 Ammo Caliber 25 Auto (ACP) Manufacturer SKU 25AP Primer Type Boxer Magnetic No UPC Barcode 762344860206 Cost Per Round 44.9¢ per round The 25 ACP was developed just after the turn of last century by John Browning, just like many of the rounds we still use today. Created to give the performance of the 22 LR to the pistol platform, the 25 ACP is a fantastic, low recoil round for self defense or training at the range. With its incredibly small kick and its great accuracy, you won't have any trouble shooting this over one hundred year old round.

Fiocchi is the oldest ammunition and firearms manufacturer in Italy and is still run and owned by the same family that started it, still creating some of the best products in the world. Firing at 800 feet per second, these 50 grain, brass cased, boxer primed, full metal jacket rounds have just the accuracy and incredible reliability you need for all your handgun training needs.

-

Fiocchi 5.56x45 55 Grain FMJBT M193 – 1000 Rounds

$454.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 55 Grain Bullet Type Full Metal Jacket Boat Tail (FMJ-BT) Use Type plinking at the range Casing Type Brass Quantity 1000 Ammo Caliber 5.56x45mm Manufacturer SKU 556M193L Primer Type Boxer Magnetic No UPC Barcode 762344864259 Cost Per Round 45.5¢ per round Although it performs nearly identically to their premiere Exacta line of ammunition, Fiocchi’s Shooting Dynamics ammo is priced so you can train longer and get more out of your trips to the range. These 1,000 rounds are not remotely wanting in the quality department -- their brass casings are fresh from the factory (possibly in Italy, more likely in Ozark, MO), their Boxer primers are responsive and non-corrosive, and their propellant is clean burning and matched to deliver a consistent chamber pressure, shot after shot.

This M193 Ball round boasts a 55 grain projectile with a full metal jacket, so it’ll feed without issue in your AR-15 and penetrate even unconventional plinking targets. The bullet further features a boat tail design, so its ballistic coefficient is high to give it a flattened trajectory, lower sensitivity to crosswinds, and the ability to retain a better part of its velocity downrange. -

Fiocchi Low Recoil Target Load 20 Gauge 2-3/4" 3/4 oz. #7-1/2 – 250 Rounds

$114.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 3/4 oz. Bullet Type #7-1/2 Shot Use Type Subsonic, target practice and clay shooting, trapshooting and busting up clays Quantity 250 Ammo Caliber 20 Gauge Manufacturer SKU 20LITE75 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344852171 Cost Per Round 45.9¢ per round If you're looking for a good load for Subsonic, target practice and clay shooting, trapshooting and busting up clays, you've come to the right page. This 20 Gauge ammo for sale features a 2-3/4" shell with Lead shot. New from Fiocchi, you will get excellent performance shot after shot as you work your way through all 250 of these rounds. Plus, when you buy from Widener's, you know you'll get fast shipping with a customer service team that stands behind everything we sell. -

Fiocchi Game and Target 12 Gauge 2-3/4" 1 oz. #8 - 25 Rounds

$11.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1 oz. Bullet Type #8 Shot Use Type hunting upland birds, target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12GT8 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344700106 Cost Per Round 47.4¢ per round When you want something with incredible power and that produces fantastic results, the 12 gauge shotgun is the perfect firearm for you. Developed in the 1870's, the 12 gauge has been used all over the world for years in militaries, law enforcement agencies, and by civilians, proving just how effective and reliable it is. Whether you want to hunt and put food on the table, blast clay targets, or defend your family from intruders, the 12 gauge is the perfect firearm for you.

Fiocchi has been around for nearly a century and a half and is still owned by the same family that founded it, making it one of the most respected firearms and ammunition manufacturers in the world. Firing at 1250 feet per second, these Fiocchi Game and Target, 2 3/4", #8 shot, one ounce shells have all the power, great patterns, and energy you need to not only blast clay targets, but take down upland game for your supper as well.

-

Fiocchi Pistol Shooting Dynamics 38 Special 130 Grain FMJ - 50 Rounds

$23.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 130 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range, Subsonic Casing Type Brass Quantity 50 Ammo Caliber 38 Special Manufacturer SKU 38A Primer Type Boxer Magnetic No UPC Barcode 762344705101 Cost Per Round 47.7¢ per round This .38 Special ammunition from Fiocchi excels in the training role, delivering solid accuracy and realistic ballistics at a low cost. A relatively "hot" standard pressure load, this ammo fires a 130 grain full metal jacket bullet at 950 feet per second, making it a good stand-in for expensive defensive cartridges.

These rounds can also be used as an inexpensive range load for .357 Magnum revolvers. However, they may not be suitable for use in all rifles with tubular magazines due to their jacketed construction.

These cartridges come in boxes of 50 and use non-corrosive Boxer primers and reloadable brass cases. -

Fiocchi 5.7x28mm 40 Grain FMJ – 450 Rounds

$219.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 40 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 450 Ammo Caliber 5.7x28mm Manufacturer SKU 57FMJ40 Primer Type Boxer Magnetic No UPC Barcode 762344865676 Cost Per Round 48.9¢ per round Are you fresh out of 5.7x28mm ammunition? That’s a horrible way to be! Thankfully we’ve got Fiocchi, which produces their Range Dynamics line of ammunition right in the heart of America. It’ll keep your high-velocity .22 cal pistol ready for any kind of target shooting or plinking you could come up with!

Cursory inspection of this round’s 40 grain projectile will reveal that it is not engineered for self-defense applications. It hasn’t got a polymer tip set above a nose cavity – just a streamlined solid point profile that helps to conserve downrange momentum. The full metal jacket doesn’t contain any metals that could attract a magnet. Fire the lead-core copper-jacket bullet at any range you care to grace with your presence and you’ll be just fine.

Fiocchi doesn’t release a 5.7x28mm cartridge to the public unless it is outfitted with a new and reusable brass case, sensitive and noncorrosive Boxer primer, and uniform charge of clean-burning powder. Safe chamber pressures and clockwork cycling can be yours soon – order today and behold our fast shipping in action! -

Fiocchi 12 Gauge 2-3/4" #1 Buck – 250 Rounds

$124.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight Not Applicable Bullet Type #1 Buck Use Type home defense, hunting or defending your home Quantity 250 Ammo Caliber 12 Gauge Manufacturer SKU 12EX9P Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344865805 Cost Per Round 49.9¢ per round Don’t feel like you’re obligated to only use Fiocchi Defense Dynamics 12 Gauge ammunition for personal protection. We have no doubt this shell could bag a coyote or a whitetail, and its utility at the target range is not debatable. But if you’re ever forced to defend yourself, you’ll be very glad to have this ammo on your side.

This shotgun shell is loaded with nine pellets of #1 buckshot. The #1 buck pellet weighs about 40.5 grains, which gives it comparably striking energy to a 22 LR projectile. Naturally, anything that gets hit with nine 0.30” diameter lead balls all at once is going to have a major problem.

Why is this shell loaded with #1 buck instead of tried-and-true double-aught? A couple reasons. First, its lighter shot column translates to reduced recoil – as well as less muzzle flip, which can help you line up follow-up shots faster. Second, the #1 buck pellet’s lower momentum decreases its risk of passing through a threat and/or multiple sheets of drywall. It’s not a guarantee against over-penetration, but it does reduce the risk of it all the same. -

Fiocchi CRUSHER 12ga 2 3/4" 1oz. #8 Shot Target - 25 Rounds

$12.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1 oz. Bullet Type #8 Shot Use Type trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12CRSR8 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344702339 Cost Per Round 51.4¢ per round An excellent 12 Gauge load manufactured by Fiocchi that promises excellent performance and reliable feeding/extraction round after round. These are new 2-3/4" shells loaded with Lead shot, you'll have 25 rounds ready for your next trapshooting and busting up clays. -

Fiocchi Target 12 Gauge 2-3/4" 1 oz. #8 – 25 Rounds

$12.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1 oz. Bullet Type #8 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12SD1L8 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344705538 Cost Per Round 51.4¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 12 Gauge rounds are no exception. In this 25 round package, you'll be set for your next trip with your 12 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round. -

25rds - 12 Gauge Fiocchi Target Shooting Dynamics 2 3/4" 1 1/8oz. #7 1/2 Shot Ammo

$12.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/8 oz. Bullet Type #7-1/2 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12SD18H7 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344705606 Cost Per Round 51.4¢ per round A great option for your 12 Gauge shotgun! These Fiocchi rounds have a shell_length of 2-3/4" and are loaded with Lead shot that make them an ideal choice for target practice and clay shooting, trapshooting and busting up clays. These are New rounds so you can focus on your surroundings knowing that you'll get reliable performance from each round. -

Fiocchi 357 Mag 142 Grain FMJTC - 50 Rounds

$25.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 142 Grain Bullet Type Full Metal Jacket Truncated Cone (FMJTC) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 357 Magnum Manufacturer SKU 357F Primer Type Boxer Magnetic No UPC Barcode 762344001319 Cost Per Round 51.7¢ per round This .357 Magnum ammo from Fiocchi's economical "Pistol Shooting Dynamics" line is an excellent option for plinking, practice, and match use. Each cartridge is assembled using a reloadable brass casing, a standard clean-burning powder charge, a non-corrosive Boxer primer, and a Full Metal Jacket projectile with a Truncated Cone (FMJTC).

FMJTC rounds are popular with competitors because they leave nice clean holes in paper and cardboard targets without sacrificing accuracy and stability at longer ranges. The bullets weigh 142 grains which is a median for the caliber and will boast comparable recoil to most defensive loads without being so fierce as to discourage extended range trips.

The cartridge casings are crimped to their respective projectile's cannelures which prevents bullet setback or dislodging caused by recoil while sitting in the cylinder. Fiocchi ammunition is manufactured in Italy using processes and techniques that have been passed down and refined since 1876.

Customer Reviews

-

Easiest way to purchase ammo.

-

Easiest way to purchase ammo. Wasted my time going to a variety of stores and not finding the ammo. Thank you Wideners.

Review by Oscar (Posted on 2/11/2022)

-

-

Fiocchi 20 Gauge 2-3/4" 7/8 oz. #8 – 250 Rounds

$129.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 7/8 oz. Bullet Type #8 Shot Use Type target practice and clay shooting Quantity 250 Ammo Caliber 20 Gauge Manufacturer SKU 20VIPH8 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344852270 Cost Per Round 51.9¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 20 Gauge rounds are no exception. In this 250 round package, you'll be set for your next trip with your 20 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round. -

Fiocchi 5.56x45mm 55 Grain FMJBT M193 – 50 Rounds

$26.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 55 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 5.56x45mm Manufacturer SKU 556M193L Primer Type Boxer Magnetic No UPC Barcode 762344712062 Cost Per Round 53.7¢ per round This 5.56x45mm cartridge is from Fiocchi’s Shooting Dynamics line of ammunition, and accordingly will deliver high performance out of your rifle without breaking the bank. The Italian manufacturer pours intense quality into each of their rounds’ components, so this one’s factory fresh brass casing, sensitive and non-corrosive primer, and clean burning propellant are all poised to make your precious time at the range as rewarding as can be.

This is an M193 cartridge, the same type that is commonly issued for field use in the M16A1 rifle. Its lead alloy core is wrapped in a gilded metal jacket, so it can penetrate many types of common barriers and prevent excessive fouling from quickly impacting your firearm’s accuracy. This bullet further features a tapered base, and as the result is highly accurate courtesy of its flattened trajectory, ability to resist the influence of cross winds, and tendency to keep much of its velocity even after having flown far downrange. -

Fiocchi 410 Bore 1/2 oz. #8 – 250 Rounds

$134.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1/2 oz. Bullet Type #8 Shot Use Type hunting upland birds Quantity 250 Ammo Caliber 410 Gauge Manufacturer SKU 410GT8 Shot Material Lead Shell Length 2-1/2" Magnetic No UPC Barcode 762344852454 Cost Per Round 53.9¢ per round Are running dangerously low on the 410 Bore ammunition you need to hunt dove, quail and other small game? Or do you just have a Taurus Judge or S&W Governor, and want some good ammo for plinking fun? Then you’d better sit down before you continue reading.

Seriously, last warning: have a seat before you read the life-changing news we’re about to unveil.

We have Fiocchi Dove & Quail 410 Bore ammunition in stock! These Missouri-made 2-1/2” hunting rounds are loaded with half-ounce payloads of #8 lead shot, recoil-reducing hinged wads, and the clean-burning powder they need to treat you to a real steady muzzle velocity of 1,200 fps. Fiocchi’s clever wad design also helps prevent shot deformation before it can weaken pattern density, which alongside their highly uniform 0.090” diameter pellets assures the predictable performance you need to do your best shooting.

Fiocchi’s hulls are reloadable! Keep them and use them to load your own high-quality 410 Bore ammo back at home. -

Fiocchi 357 Mag 142 Grain FMJTC - 1000 Rounds

$549.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 142 Grain Bullet Type Full Metal Jacket Truncated Cone (FMJTC) Use Type plinking at the range Casing Type Brass Quantity 1000 Ammo Caliber 357 Magnum Manufacturer SKU 357F Primer Type Boxer Magnetic No UPC Barcode 762344045856 Cost Per Round 55¢ per round If you are looking for an affordable, yet quality, option for volume shooting, look no further. This 357 Magnum ammo has full metal jacket projectiles with a cone shaped nose with the tip cut off. This design allows for reliable feeding in semi-automatic pistols, and greater accuracy from longer distances.

Since 1876, Fiocchi has been innovating new ideas to improve the quality of their products for shooters worldwide. As a family-owned business, Fiocchi continues to put business-savvy ideas in motion while maintaining affordability in their products. You can't go wrong with this ammunition. Buy yours today and shoot away! -

Fiocchi White Rino 12 Gauge 2-3/4" 1-1/8 oz. #8 – 25 Rounds

$13.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/8 oz. Bullet Type #8 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12WRNO8 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344701660 Cost Per Round 55.4¢ per round The 12 gauge shotgun has been around for nearly one hundred fifty years and is still one of the best, close range firearms on the market. Used all over the world for military, civilian, and law enforcement service, this amazing shotgun has proven time and again its incredible efficacy and power. Whether you are looking to hunt, destroy clay targets at the range, or stop an intruder from harming your family, the 12 gauge is perfect for you.

Since 1876, Fiocchi has put out some of the best ammunition in the world and is still owned and managed by the founding family. Fiocchi of America is located in Ozark, Missouri and produces more of the ammunition fold in the states.

These Fiocchi White Rino shells are from the Exacta Target line which is designed to deliver reliable performance at an affordable price. Each hull measures 2-3/4" in length and carries 1-1/8 ounce of #8 shot. Firing at 1250 feet per second, these shells are optimized for busting clays at the range.

-

Fiocchi Game and Target 12 Gauge 2-3/4" 1 oz. #7-1/2 – 25 Rounds

$13.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1 oz. Bullet Type #7-1/2 Shot Use Type hunting upland birds, target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12GT75 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344700090 Cost Per Round 55.4¢ per round A great option for your 12 Gauge shotgun! These Fiocchi rounds have a shell_length of 2-3/4" and are loaded with Lead shot that make them an ideal choice for hunting upland birds, target practice and clay shooting, trapshooting and busting up clays. These are New rounds so you can focus on your surroundings knowing that you'll get reliable performance from each round.Customer Reviews

-

Great Service!

-

My order arrived quickly thanks to the Great service provided by the staff. Will recommend this site to my family and friends.

Review by Huz (Posted on 12/7/2020)

-

-

Fiocchi White Rino 12 Gauge 2-3/4" 1-1/8 oz. #7.5 – 25 Rounds

$13.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/8 oz. Bullet Type #7-1/2 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12WRNO75 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344701653 Cost Per Round 55.4¢ per round If you're looking for a good load for target practice and clay shooting, trapshooting and busting up clays, you've come to the right page. This 12 Gauge ammo for sale features a 2-3/4" shell with Lead shot. New from Fiocchi, you will get excellent performance shot after shot as you work your way through all 25 of these rounds. Plus, when you buy from Widener's, you know you'll get fast shipping with a customer service team that stands behind everything we sell. -

Fiocchi Exacta Target 410 Bore 1/2 oz. #8 – 250 Rounds

$144.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1/2 oz. Bullet Type #8 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 250 Ammo Caliber 410 Gauge Manufacturer SKU 410VIP8 Shot Material Lead Primer Type Shotshell Shell Length 2-1/2" Magnetic No UPC Barcode 762344852478 Cost Per Round 57.9¢ per round Your quest to destroy clay never ends. And you’re not content to make things easy on yourself by shooting a 12 or a 20. No. Skill like yours can only truly shine when you’re shouldering the svelte 410 Bore.

Show everyone that size doesn’t matter. Order 250 two-and-a-half inchers by Fiocchi and become the tornado of clay destruction you were always meant to be!

Whether you’re firing the longest-barreled shotgun you can get your hands on or a decidedly smaller S&W Governor (or other 410/45 handgun), you can count on Fiocchi to supply the tight pattern you want. This shotgun shell’s #8 shot is made of first run chilled lead. It’s hard. All 0.5 ounces of it are cradled by a premium one-piece wad, which is cushioned to help mitigate recoil and keep those shot pellets aerodynamically spherical. The little shell’s light payload reveals itself at 1,250 fps muzzle velocity, so you’ll have all the energy you need to intercept even the farthest and fastest of clays. Order today! -

Fiocchi 5.7x28mm 40 Grain Polymer Tipped – 500 Rounds

$289.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 40 Grain Bullet Type Polymer Tipped Use Type home defense Casing Type Brass Quantity 500 Ammo Caliber 5.7x28mm Manufacturer SKU 57PT40 Primer Type Boxer Magnetic No UPC Barcode 762344864471 Cost Per Round 58¢ per round 5.7x28mm would be a lot more popular if it were easier to find. And if it were easier to find, many more shooters would love it. That’s what we call a catch-22. But you’re already converted, which is why you’re sure to really dig Fiocchi’s Hyperformance Defense series self-defense ammunition!

Fiocchi produces SS197SR spec 5.7x28 ammo for FN Herstal. This is fundamentally the same exact cartridge, complete with a 40 grain polymer tipped hollow point projectile. In addition to the bullet’s balanced lead core and concentric copper-alloy jacket, the tip helps to promote greater accuracy by significantly streamlining the bullet’s frontal profile. But the tip also remains functional after impact. It drives into the bullet’s concealed nose cavity, commencing rapid terminal expansion that transfers kinetic energy outward.

This smooth-feeding, noncorrosive, Boxer-primed, brass-cased, reloadable and American-made ammo is suitable for all 5.7x28 firearms, including the FN Five-seveN, Ruger-57 and AR-57. -

Fiocchi 223 Rem 55 Grain FMJ – 50 Rounds

$29.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 55 Grain Bullet Type Full Metal Jacket Boat Tail (FMJ-BT) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 223 Remington Manufacturer SKU 223A Primer Type Boxer Magnetic No UPC Barcode 762344704968 Cost Per Round 59.7¢ per round Get in your range time without breaking the bank, with this Fiocchi 223 Remington ammunition.

This ammunition is loaded with a 55 grain full metal jacket bullet, and has muzzle velocities of about 3,200 feet per second. This ammo is great for all types for range training and tactical training, including high precision marksmanship training. This ammo is also cheap enough to make a good plinking round and accurate enough to be used with hunting small varmints, although it does not expand on impact with its target.

This box of 50 rounds is loaded by the increasingly popular Fiocchi Ammunition Company. Fiocchi produces a wide variety of range training, self defense, and hunting ammunition, and is sold in the US and several other countries around the world. The Italian based ammo manufacturer primarily produces quality yet affordable brass cased ammunition and uses a variety of projectiles made both in-house and by other highly reputable companies. Order your ammo today, and safe shooting!

-

Fiocchi Shooting Dynamics 12 Gauge 2-3/4" 1-1/8 oz. #8 – 25 Rounds

$15.00Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/8 oz. Bullet Type #8 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12SD18L8 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344705590 Cost Per Round 60¢ per round These standard 12 gauge target loads from Fiocchi are great for new shooters as well as for experienced skeet competitors who want to lighten their felt recoil without taking a handicap. Fiocchi is an Italian company with over 140 years of experience manufacturing handgun, rifle, and shotgun cartridges for sporting and law enforcement use. In the U.S., their boxes are recognized as a dependable source of clean, affordable ammo. Most of the ammunition that they sell in America is made at their facility in Ozark, Missouri and utilizes components sourced from the country as well.

Components include high-brass heads, clean-igniting 209 primers, and hardened lead shot which patterns tightly and destroys clay pigeons with shattering authority. The white shells have a raised and rolled rim for smooth loading and have an extended shell length of 2-3/4 inches; this offers the greatest range of compatibility with shotguns of any action and type.

-

Fiocchi 223 Rem 62 Grain FMJBT – 50 Rounds

$30.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 62 Grain Bullet Type Full Metal Jacket Boat Tail (FMJ-BT) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 223 Remington Manufacturer SKU 223C Primer Type Boxer Magnetic No UPC Barcode 762344706580 Cost Per Round 61.7¢ per round Do you frequent a rifle range that forbids magnetic ammunition on its premises, but still want to fire 5.56x45 M855 ammunition? Lo and behold – the perfect substitute, courtesy of Fiocchi! This Missouri-made 223 Rem range ammunition is loaded with 62 grain bullets and delivers a muzzle velocity of 3,000 fps. Those stats make this nonmagnetic ammo’s ballistic performance almost indistinguishable from that of our military’s penetrator load!

This round’s bullet is more than just nonmagnetic. As a full metal jacket boat tail it features a slightly tapered base which minimizes drag to help conserve downrange momentum, an evenly distributed jacket and core which assure satisfactory in-flight stability, and a ballistically efficient solid point profile. Don’t expect terminal expansion from an FMJBT – but don’t expect a varmint to survive an encounter with one, either.

Fiocchi fits each one of these rounds with a virgin brass case, noncorrosive Boxer primer and charge of low-residue propellant. A swell choice for any 5.56/223 rifle, semi-automatic or otherwise!Customer Reviews

-

Positive

-

The Hickock45 discount was a buying incentive as well as buying from a company in a Free state,

Review by DrC (Posted on 11/17/2023)

-

-

Fiocchi Optima Specific HV 12 Gauge 2-3/4" 1-1/4 oz. #8 – 250 Rounds

$154.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/4 oz. Bullet Type #8 Shot Use Type hunting upland birds Quantity 250 Ammo Caliber 12 Gauge Manufacturer SKU 12HV8 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344851044 Cost Per Round 61.9¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 12 Gauge rounds are no exception. In this 250 round package, you'll be set for your next trip with your 12 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round. -

Fiocchi 410 ga 2-1/2" #8 Target - 25 Rounds

$15.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1/2 oz. Bullet Type #8 Shot Use Type target practice and clay shooting Quantity 25 Ammo Caliber 410 Gauge Manufacturer SKU 410VIP8 Shot Material Lead Shell Length 2-1/2" UPC Barcode 762344704838 Cost Per Round 63.4¢ per round An excellent 410 Gauge load manufactured by Fiocchi that promises excellent performance and reliable feeding/extraction round after round. These are new 2-1/2" shells loaded with Lead shot, you'll have 25 rounds ready for your next target practice and clay shooting. -

Fiocchi HV 12 Gauge 2-3/4" 1-1/4 oz. #6 – 250 Rounds

$164.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/4 oz. Bullet Type #6 Shot Use Type hunting upland birds Quantity 250 Ammo Caliber 12 Gauge Manufacturer SKU 12HV6 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344851020 Cost Per Round 65.9¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 12 Gauge rounds are no exception. In this 250 round package, you'll be set for your next trip with your 12 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round. -

Fiocchi Extrema 223 Rem 50 Grain V-MAX – 1000 Rounds

$659.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 50 Grain Bullet Type V-MAX Use Type varmint hunting Casing Type Brass Quantity 1000 Ammo Caliber 223 Remington Manufacturer SKU 223HVA50 Primer Type Boxer Magnetic No UPC Barcode 762344862286 Cost Per Round 66¢ per round The 223 Rem has been around since 60's and it has only gone up in popularity since that time. With its incredible accuracy, light weight, fantastic speed, and low recoil, this round is used around the world for hunting, varmint exterminating, defending yourself, and competing in shooting matches.

Since 1876, Fiocchi has been owned and managed by the same family that founded it. In order to be competitive in the American market, Fiocchi established a manufacturing facility in Missouri that produces a majority of the rounds that are sold in the USA.

These Extrema rounds come equipped with Hornady V-Max bullets, giving you rapid and explosive expansion for quick and clean varmint kills. These 50 grain polymer tipped projectiles are pressed into reloadable boxer primed brass cases.

-

Fiocchi 20 Gauge 2-3/4" 7/8 oz. #8 – 25 Rounds

$16.55Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 7/8 oz. Bullet Type #8 Shot Use Type target practice and clay shooting Quantity 25 Ammo Caliber 20 Gauge Manufacturer SKU 20VIPH8 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344704753 Cost Per Round 66.2¢ per round An excellent 20 Gauge load manufactured by Fiocchi that promises excellent performance and reliable feeding/extraction round after round. These are new 2-3/4" shells loaded with Lead shot, you'll have 25 rounds ready for your next target practice and clay shooting. -

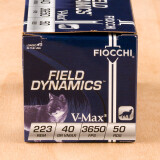

Fiocchi Extrema 223 Rem 40 Grain Polymer Tip V-MAX - 1000 Rounds

$664.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 40 Grain Bullet Type V-MAX Use Type varmint hunting Casing Type Brass Quantity 1000 Ammo Caliber 223 Remington Manufacturer SKU 223HVB50 Primer Type Boxer Magnetic No UPC Barcode 762344862071 Cost Per Round 66.5¢ per round Got a serious pest problem? Fiocchi has a serious pest solution. This 1,000 round case of .223 Remington ammunition from Fiocchi is sure to put a stop to any varmint's plans in a hurry.

Each cartridge in this case fires a light 40 grain Hornady V-MAX bullet at a muzzle velocity of 3,650 feet per second. The V-MAX is a polymer tipped, jacketed hollow point projectile that delivers rapid fragmentation for a quick kill against small animals.

Fiocchi of America is based in Ozark, Missouri and produces a wide variety of ammo that makes up the bulk of Fiocchi products sold in the US. Hornady bullets are made in Grand Island, Nebraska. This ammunition uses non-corrosive primers and reloadable brass cases.

-

Fiocchi High Velocity 20 Gauge 2-3/4" 1 oz. #6 – 25 Rounds

$16.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1 oz. Bullet Type #6 Shot Use Type hunting upland birds Quantity 25 Ammo Caliber 20 Gauge Manufacturer SKU 20HV6 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344700960 Cost Per Round 67.4¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 20 Gauge rounds are no exception. In this 25 round package, you'll be set for your next trip with your 20 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round. -

Fiocchi Little Rino 12 Gauge 2-3/4" 1 oz. #8 – 25 Rounds

$16.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1 oz. Bullet Type #8 Shot Use Type target practice and clay shooting, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12TX8 Shot Material Lead Shell Length 2-3/4" Magnetic No UPC Barcode 762344701134 Cost Per Round 67.4¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 12 Gauge rounds are no exception. In this 25 round package, you'll be set for your next trip with your 12 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round. -

Fiocchi Optima Specific HV 12 Gauge 2-3/4" 1-1/4 oz. #8 – 25 Rounds

$16.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/4 oz. Bullet Type #8 Shot Use Type hunting upland birds, trapshooting and busting up clays Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12HV8 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344700304 Cost Per Round 67.4¢ per round If you're looking for a good load for hunting upland birds, trapshooting and busting up clays, you've come to the right page. This 12 Gauge ammo for sale features a 2-3/4" shell with Lead shot. New from Fiocchi, you will get excellent performance shot after shot as you work your way through all 25 of these rounds. Plus, when you buy from Widener's, you know you'll get fast shipping with a customer service team that stands behind everything we sell. -

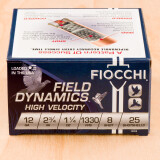

Fiocchi High Velocity 12 Gauge 2-3/4" 1-1/4 oz. #7-1/2 – 25 Rounds

$16.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/4 oz. Bullet Type #7-1/2 Shot Use Type hunting upland birds Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12HV75 Shot Material Lead Primer Type Shotshell Shell Length 2-3/4" UPC Barcode 762344700281 Cost Per Round 67.4¢ per round For improved reach and power in the field with your 12 gauge, try this high velocity load from Fiocchi. These shells are suitable for both upland bird and clay target shooting, performing well at extended range thanks to their high-velocity configuration.

These 2-3/4" shells come in boxes of 25 and fire a 1-1/4 oz. payload of #7.5 shot at a muzzle velocity of 1,330 feet per second.

Fiocchi of America is based in Ozark, Missouri and produces the majority of Fiocchi shotshells sold in the USA.

-

Fiocchi 45 ACP 230 Grain JHP – 50 Rounds

$34.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 230 Grain Bullet Type Jacketed Hollow-Point (JHP) Use Type home defense, Subsonic Casing Type Brass Quantity 50 Ammo Caliber 45 ACP (Auto) Manufacturer SKU 45T500 Primer Type Boxer Magnetic No UPC Barcode 762344701462 Cost Per Round 69.7¢ per round Fiocchi is an Italian manufacturer with over a century of experience alongside a reputation for crafting ammo for law enforcement agencies and competitive shooting teams both in the United States and all over Europe. The majority of their American-sold ammo is made in the U.S. as well, allowing them to tailor the ammo with direct feedback and utilize classic Western components for dependable performance. In this .45 ACP loads, parts include non-corrosive Boxer primers fitted to reloadable brass casings that carry clean-burning powder.

As a self-defense cartridge, the round is topped a JHP (jacketed hollow point) projectile which features a deep cavity and precisely skived copper jacket for reliable expansion as well as a gently sloping ogive for smooth feeding in semi-automatic handguns and carbines. A projectile weight of 230 grains matches the majority of trusted .45 Auto configurations and familiar cycling characteristics alongside subsonic muzzle velocity for suppressed home-defense pistols. Upon impact with a threat, the heavyweight projectile will experience an expansive increase in diameter, causing it to throw more energy into the target and create a more effective wound cavity while losing its potential for lethal over-penetration.

-

Fiocchi 357 Sig 124 Grain FMJTC – 50 Rounds

$34.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 124 Grain Bullet Type Full Metal Jacket Truncated Cone (FMJTC) Use Type plinking at the range Casing Type Brass Quantity 50 Ammo Caliber 357 Sig Manufacturer SKU 357SIGAP Primer Type Boxer Magnetic No UPC Barcode 762344028156 Cost Per Round 69.7¢ per round Match popular defensive ballistic performance choices at your next match or practice session with these .357 SIG rounds from Fiocchi. These rounds are constructed using non-corrosive Boxer primers fitted into reloadable brass casings which are topped with full metal jacket - truncated cone (FMJ-TC) projectiles. FMJ-TC bullets have a sloping conical ogive and a flat top surface (similar to a semi-wadcutter) which leaves nice clean holes in paper and cardboard targets for match scoring. The FMJ-TC shape also reflects a common profile for many .357 SIG hollow-point rounds so that your practice ammo can proof cycling and feeding for your carry/duty ammo.

These bullets weigh in at 124 grains which is light for the caliber and produces an relatively high muzzle velocity of 1,350 feet-per-second. The light weight provides a lighter recoil for the high pressure round while also mirroring the firing and flight characteristics of many .357 SIG defensive cartridges which use 124 grain Hornady XTP projectiles.

Fiocchi is one of Italy's oldest and largest ammunition manufacturers and is located in Lecco at the heart of a close-knit firearms industry community. With nearly 140 years of experience behind them, Fiocchi is one the world leaders in ammo innovation with products aimed to pleased hunters, competitive shooters, law enforcement agencies, and private citizens.

-

Fiocchi 38 S&W 145 Grain FMJ - 50 Rounds

$34.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 145 Grain Bullet Type Full Metal Jacket (FMJ) Use Type plinking at the range, Subsonic Casing Type Brass Quantity 50 Ammo Caliber 38 Smith & Wesson (S&W) Manufacturer SKU 38SWSHA Primer Type Boxer UPC Barcode 762344000985 Cost Per Round 69.7¢ per round Can't get .38 S&W ammunition locally? Never fear, Widener's has you covered! These .38 S&W (not to be confused with .38 Super or .38 Special) cartridges from Fiocchi deliver good accuracy at a reasonable price.

Each round in this box of 50 fires a 145 grain full metal jacket bullet at 780 feet per second. Unlike lead round nose loads, this ammo is generally welcome at all indoor ranges.

This ammo is made in Italy using non-corrosive Boxer primers and reloadable brass cases.

-

Fiocchi 10mm Auto 180 Grain JHP – 500 Rounds

$349.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 180 Grain Bullet Type Jacketed Hollow-Point (JHP) Use Type home defense Casing Type Brass Quantity 500 Ammo Caliber 10mm Auto Manufacturer SKU 10APHP Primer Type Boxer Magnetic No UPC Barcode 762344864044 Cost Per Round 70¢ per round Picture a world without Jacuzzis, Moon Boots, opera houses, parachutes, or stilettos. Is that really a world that you want to live in? Thank goodness we were blessed with Italy, a country responsible for some of mankind’s greatest feats of innovation. Just to sweeten the deal Italy also gave us Fiocchi, which makes a wide variety of economical yet high quality ammo like this 10mm Shooting Dynamics cartridge.

This round is optimal for self-defense thanks to its 180 grain jacketed hollow point projectile. The bullet’s jacket wears little notches pressed around its tip, which serve to ensure that fast expansion occurs along a preset path for unerringly deadly terminal effect. The bullet’s strong and concentric jacket promotes proper penetration and rotational stability in flight, respectively, so its as trustworthy in a self-defense scenario as it is rewarding practice at the range. Fiocchi’s state of the industry manufacturing process yields great brass casings, Boxer primers, and fast burning propellant which are all front and center in this round. -

Fiocchi 410 Bore 11/16 oz. #6 – 25 Rounds

$18.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 11/16 oz. Bullet Type #6 Shot Use Type hunting upland birds Quantity 25 Ammo Caliber 410 Gauge Manufacturer SKU 410HV6 Shot Material Lead Shell Length 3" Magnetic No UPC Barcode 762344703602 Cost Per Round 75.4¢ per round The war against upland game is never-ending. That means you need a constant supply of 410 Bore ammunition – preferably American-made.

Fiocchi’s Field Dynamics line of ammunition hails from the great state of Missouri. That’s where these 3” birthday candles were equipped with their hot and reliable noncorrosive primers, fast-igniting primers, and high-brass reloadable tubes. These rounds feature hinged wads, which compress so as to minimize shot deformation while simultaneously softening felt recoil.

Fiocchi arms each one of these shells with 11/16 ounces of #6 shot. It’s an ideal shot size for taking “large small” game such as grouse, partridge, squirrel and hare. The rugged solid lead pellets achieve supersonic velocity without becoming too flat to pattern evenly. They also resist deformation on impact, thus enabling them to penetrate deeply enough to deliver the quick and clean kill.

We’re the fastest shippers in the online ammunition retail business. Give us a chance to wow you! -

Fiocchi 223 Rem 40 Grain Polymer Tip V-MAX - 50 Rounds

$37.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 40 Grain Bullet Type V-MAX Use Type varmint hunting Casing Type Brass Quantity 50 Ammo Caliber 223 Remington Manufacturer SKU 223HVB50 Primer Type Boxer Magnetic No UPC Barcode 762344706597 Cost Per Round 75.7¢ per round Varmint hunters will appreciate the lethality of this .223 Remington ammunition from Fiocchi. These cartridges come in boxes of 50 and offer reliable yet cost-effective performance.

Each round in this box fires an extra-light 40 grain Hornady V-MAX hollow point bullet. The V-MAX is a polymer-tipped varmint bullet designed to fragment rapidly for a quick kill against coyotes, groundhogs, rabbits, and other pest animals.

This ammunition is loaded in Ozark, Missouri using non-corrosive Boxer primers and reloadable brass cases.

-

Fiocchi 410 Bore 11/16 oz. #7.5 – 250 Rounds

$189.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 11/16 oz. Bullet Type #7-1/2 Shot Use Type hunting upland birds Quantity 250 Ammo Caliber 410 Gauge Manufacturer SKU 410HV75 Shot Material Lead Shell Length 3" Magnetic No UPC Barcode 762344852508 Cost Per Round 75.9¢ per round What’s that? You’re still hunting upland game with 2-1/2” 410 Bore ammo? Ha ha ha! Oh wait. You’re being serious. Here, let us laugh in italics: Ha ha ha!

Phew. We’re sorry, it’s just really funny to us that you’d choose 2-1/2” hunting ammo when you could enlist the commanding stopping power of these 3” rounds by Fiocchi!

This shell is longer for good reason: it holds a whopping 11/16 ounces of shot! And not just any shot – #7.5 shot, which translates to a dense, deadly cloud of around 240 pellets. Fiocchi casts each pellet out of stiff lead to prevent deformation, screens it multiple times to ensure it is a true 0.095” in diameter, and backs it with the low-fouling powder it requires to zip out of a shotgun’s barrel at a steady rate of 1,140 feet per second. No dove will be safe from your fury!

This ammo is loaded with reloadable hulls, so the fun doesn’t have to end once you’ve emptied your last of 10 boxes. And don’t forget: we sell T-shirts, too. -

Fiocchi Optima Specific High Velocity 12 Gauge 2-3/4" 1-1/4 oz. #6 – 25 Rounds

$19.00Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 1-1/4 oz. Bullet Type #6 Shot Use Type hunting upland birds Quantity 25 Ammo Caliber 12 Gauge Manufacturer SKU 12HV6 Shot Material Lead Shell Length 2-3/4" UPC Barcode 762344700274 Cost Per Round 76¢ per round Fiocchi produces some of the best shotgun loads in the world and these 2-3/4" 12 Gauge rounds are no exception. In this 25 round package, you'll be set for your next trip with your 12 Gauge shotgun. Loaded with Lead shot, these are New rounds that promise reliable firing round after round.Customer Reviews

-

Excellent shells for my new VIPR-12 Shotgun that required higher FTS shells and these worked great.

-

I needed higher FTS shells for my new VIRP-12 shotgun and these shells worked great and everyone ejected perfectly. Great product at a good price and had them in stock where other local gun stores did not have any product that would work correctly with the new gun.

Review by Excellent (Posted on 6/1/2020)

-

-

Fiocchi Plano Ammo Can 223 Rem 40 Grain V-MAX PT – 200 Rounds

$157.85Product Type Ammo Manufacturer Fiocchi Condition New Bullet Weight 40 Grain Bullet Type V-MAX Use Type varmint hunting Casing Type Brass Quantity 200 Ammo Caliber 223 Remington Manufacturer SKU 223FHVB Primer Type Boxer Magnetic No UPC Barcode 762344863443 Cost Per Round 78.9¢ per round If you've got pesky varmints on your property, consider using this .223 Remington ammunition from Fiocchi with your AR-15 or other .223/5.56 NATO rifle to solve the problem. These cartridges come packaged in a convenient reusable black Plano ammo ammo can with a sturdy latch and carrying handle.

Each cartridge in this case of 200 fires a 40 grain polymer tipped Hornady V-MAX jacketed hollow point bullet at a muzzle velocity of 3,650 feet per second. This high velocity helps promote rapid fragmentation for efficient kills against small animals; the fast disintegration of the projectile also reduces the risk of overpenetration and ricochets.

Based in Ozark, Missouri, Fiocchi of America is the US division of Fiocchi Munizioni SPA, which was founded in Italy in 1876. Although relatively new to the US market, Fiocchi ammo has gained increasing popularity in recent years due to its reasonable price and consistent quality. Fiocchi ammo uses non corrosive Boxer primers and reloadable brass cases.