TMJ ammo stands for “Total Metal Jacket” ammunition. It refers to bullets completely encapsulated in a thin layer of copper, covering not just the sides and tip but also the bullet’s base. This design happens through an electroplating process that deposits a uniform copper coating over the entire lead core of the bullet.

TMJ bullets are designed to reduce lead exposure, particularly at indoor shooting ranges, by preventing hot propellant gases from vaporizing the lead core during firing. The uniform copper plating can contribute to slightly improved accuracy and less barrel fouling than FMJ (full metal jacket) bullets. Because it minimizes airborne lead particles, TMJ ammo is often a requirement at indoor ranges for health and safety reasons.

Materials Used In TMJ Ammo Manufacturing

TMJ bullets are composed of the following materials:

- Lead core: A dense lead core is the prominent component of a TMJ bullet. Manufacturers choose lead for its high density, malleability, and cost-effectiveness, making it ideal for bullet manufacturing.

- Copper jacket: A thin jacket of copper, applied using electroplating, completely encapsulates the lead.

- Alternative materials: Although copper is the most common material used for the jacket, other ductile metals, such as brass, may be used in some cases. However, copper remains the standard due to its balance of ductility, corrosion resistance, and performance.

TMJ Ammo Plating Process

Total metal jacket bullets are a product of electroplating manufacturing, setting them apart from traditional FMJ rounds.

The process begins with a fully formed lead core, which enters an electrified chemical bath containing a copper solution. Through electrolysis, copper ions are deposited onto the lead core one atom at a time, building up a thin, uniform copper jacket that completely encapsulates the core, including the bullet’s base. The result is a bullet with no exposed lead, as the copper jacket covers the entire surface of the lead core.

Primary Features Of TMJ Ammo

The TMJ bullet is generally covered in a thin layer of copper, covering not just the sides and tip but also the bullet’s base.

Electroplating ensures the copper jacket is seamless and covers the entire bullet, including the base. This is not the case with FMJ bullets, where the lead base typically remains exposed. Although the copper layer created by electroplating is generally thinner than the mechanically swaged jackets found on FMJ bullets, it provides complete coverage. Electroplating is also more expensive and complex than the swaging process used for FMJ bullets, which involves pressing a lead core into a pre-formed copper jacket.

Electroplating vs. Swaging: How Do They Differ?

As mentioned, total metal jacket and full metal jacket projectiles come from separate processes: electroplating and swaging. How do they contrast?

- Electroplating uses an electric current to deposit a thin, uniform layer of copper onto a lead core submerged in a chemical solution. At the same time, swaging employs high pressure to form metal into a precise bullet shape at room temperature by pressing it into a die.

- Electroplating encapsulates the lead core with copper, creating a seamless jacket that covers the entire bullet, including the base. Swaging forms the bullet’s shape and size and can also seat a copper or brass jacket over the core.

- Electroplating builds the jacket up atom by atom using electrical current. At the same time, swaging is a mechanical process during which the jacket is expanded and formed onto the core by internal pressure.

- Electroplating provides a uniform, thin copper layer, although a secondary swaging step may refine the final dimensions. Swaging produces bullets with exact dimensions and shapes, and excellent consistency.

Why Was TMJ Ammo Developed?

TMJ ammo is well-suited for high-volume training for law enforcement and competition shooters.

Although simple, practical, and economical, many argue that the full metal jacket bullet has one major design flaw: the unjacketed base of its lead core.

Solid lead evaporates at a relatively low temperature for a metal (3,182°F). Brief exposure to exploding propellant can evaporate lead from the base of an FMJ, causing four undesirable outcomes:

- An FMJ’s base becomes slightly distorted during ignition. When propellant gases don’t have a flat, even surface to exert their energy against, accuracy can suffer.

- An FMJ produces lead gas, accumulating inside an indoor range as dust or residue.

- An FMJ creates lead gas that accumulates inside the barrel. This fouling makes the bore’s rifling less effective and harms accuracy.

- Lead gas is toxic. Exposure to lead inside gun ranges is unlikely to sicken a casual shooter. Nonetheless, serious shooters, law enforcement professionals, and range staff are all at heightened risk of lead poisoning if they endure long-term exposure to FMJ bullets within the confines of a stuffy, poorly ventilated gun range.

However, if these frequent shooters attend a range requiring TMJ ammo, as many do, their risk is significantly lower. So, to answer the original question, TMJ bullets were developed primarily to reduce lead exposure, especially at indoor shooting ranges, by preventing the vaporization of lead from the bullet base when fired. The uniform copper coating also helps reduce barrel fouling and can improve accuracy by providing a consistent base for propellant gases to push against.

TMJ Ammo Advantages

Reduced Lead Exposure

Because the TMJ process completely encapsulates the bullet, including the base, in a copper jacket, it prevents hot propellant gases from vaporizing lead during firing. This containment significantly reduces airborne lead exposure, making TMJ ammo much safer for indoor shooting ranges and shooters concerned about lead inhalation.

Cleaner Shooting Environment

Since there is no exposed lead base, TMJ bullets minimize the amount of lead and other residue left in the barrel and the air, resulting in a cleaner gun and range environment and reducing the frequency and intensity of firearm cleaning.

Improved Barrel Longevity

The complete copper jacket reduces lead fouling in the barrel, helping maintain firearm accuracy and extending the barrel’s life.

Potential For Enhanced Accuracy

TMJ bullets are electroplated, meaning they have a thinner and more uniform copper jacket than FMJ bullets. This uniformity can slightly improve accuracy due to a more consistent bullet geometry and a uniform surface for propellant gases to act upon.

Ideal For High-Volume Training

TMJ ammo is well-suited for high-volume training and law enforcement use, as it produces less residue and reduces health risks associated with lead exposure, especially in enclosed spaces like indoor ranges.

In summary, TMJ ammo offers notable health, maintenance, and performance benefits, making it a preferred choice for indoor shooters, high-volume trainers, and anyone seeking a cleaner and safer shooting experience.

TMJ Ammo Disadvantages

All good things have some downsides, and TMJ ammo is no exception.

Higher Cost

TMJ ammo is typically more expensive than the full metal jacket alternatives. The electroplating process to create the seamless copper jacket is more complex and costly than traditional FMJ manufacturing, making TMJ rounds less attractive for high-volume shooters on a budget.

Potential Jacket Shearing With Ported Barrels

The thinner, electroplated copper jacket of TMJ bullets can be vulnerable to damage when fired through firearms with ported barrels or compensators. In rare cases, a ported barrel may slice a thin sliver off the TMJ’s jacket before the bullet exits the muzzle. This sliver could eject back toward the shooter at high velocity, posing a safety risk.

Not Ideal For Self-Defense

TMJ bullets, like FMJ, do not expand upon impact. They tend to over-penetrate targets, potentially passing through and endangering bystanders or causing unintended property damage. Their lack of expansion also results in smaller wound channels, which can reduce stopping power and effectiveness in self-defense situations.

No Elimination Of Lead Exposure From Primers

Although TMJ bullets prevent lead vaporization from the bullet base, most still use traditional primers containing lead styphnate. As a result, TMJ ammo does not eliminate lead exposure, especially in poorly ventilated indoor ranges.

In summary, while TMJ ammo offers significant safety and cleanliness benefits for training and indoor range use, it is less suitable for self-defense, may cost more, and has some unique risks in specific firearm configurations.

TMJ VS FMJ: Comparison

Comparison: The exposed lead bottom of an FMJ bullet (Left), VS the plated bottom of a TMJ bullet (Right).

As mentioned, the TMJ and FMJ are both popular options, but they differ in how the lead core is encased. The jacket of the FMJ bullet covers the sides and nose of the projectile, but leaves the lead on the base exposed. The plating of the TMJ bullet covers the entirety of the projectile, while fully enclosing its lead core. Differences in the coverage of the metal jackets and platings can affect exposure to lead dust and practical accuracy.

| Feature | Total Metal Jacket | Full Metal Jacket |

| Jacket Coverage | Entire bullet, including the base. No exposed lead. | Covers the bullet except the base. Lead is exposed at the base. |

| Manufacturing | Electroplated copper jacket (thin, very uniform) | Swaged copper jacket (thicker, not over the base) |

| Lead Exposure | Greatly reduced. No lead vaporized from the base. | Some lead vaporized from the exposed base during firing. |

| Residue and Fouling | Less lead fouling. Cleaner barrels and range area. | More lead fouling from the exposed base. |

| Cost | Typically more expensive. | Usually less expensive. |

| Suitability | Preferred for indoor ranges, health-conscious shooters. | Ideal for high-volume, cost-effective training. |

| Jacket Thickness | Thinner (can be damaged by ported barrels/compensators) | Thicker (more robust for ported barrels) |

| Accuracy | Often slightly more accurate due to the uniform jacket. | Generally accurate, but the jacket may be less uniform. |

Reloading & Considerations

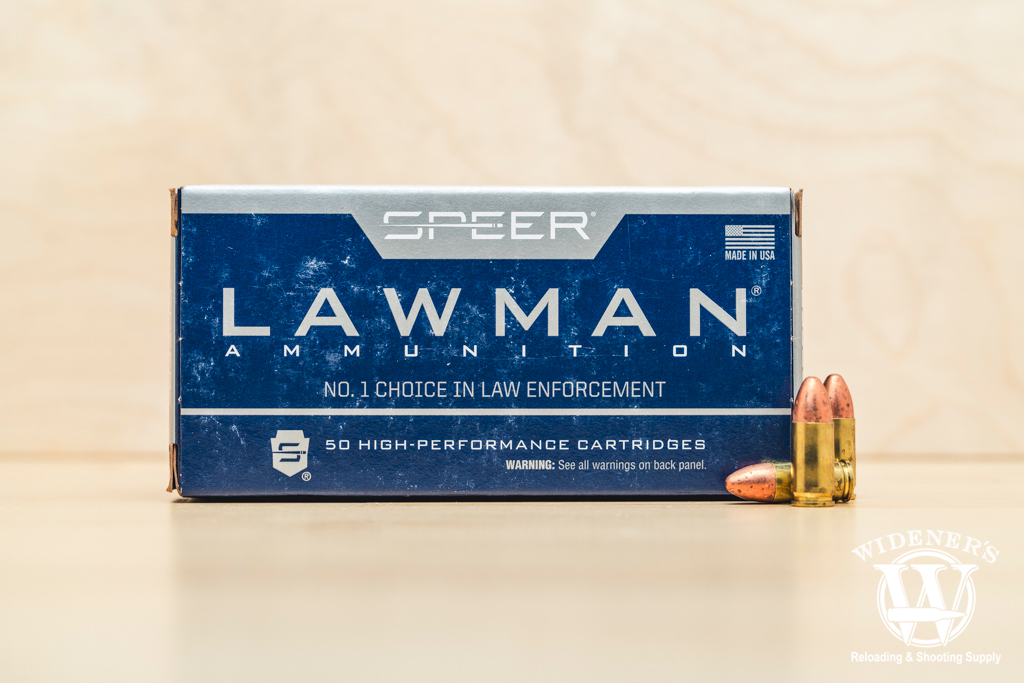

Pick up some TMJ ammo for your next range visit to reduce your exposure to lead and reduce barrel fouling.

TMJ ammo features a fully encased bullet, minimizing lead exposure and reducing firearm fouling. Because of its cleaner performance and enhanced barrel protection, it’s popular for target shooting and training. If you visit an indoor range frequently, TMJ is a better long-term option for your health. Reducing your exposure to lead is always a good thing, and the fully plated TMJ bullet helps.

Although not typically chosen for self-defense due to its penetration characteristics, TMJ Ammo remains popular among shooters seeking consistent accuracy and environmental considerations during extended practice sessions or competitions. If you’re a reloader, you’ll appreciate how clean these projectiles are when running them through your press. Keep in mind, the bullets may be velocity-limited, so plan your loads accordingly.